1k followers instagram italian restaurant rosemont il herron printing blue prada glasses nautical captain hat vinyl building material long chin beard prada sports bra chatgpt stand for instagram followers scraper fruit with spiky outside innovative print solutions prada black clutch chatgpt license instagram 5k followers aeropostale outlet mall prada leather slides gucci oficial is chatgpt detectable prada lingerie prada luna black gucci store com scrape instagram followers corkboard sheets twicsy instagram followers www gucci ca luxury designer outlet ugg mini blakely suede bootie chatgpt mba prada jordans leona lewisrun lyrics the gift aselin debison lyrics roll of cork prada sports bra stack overflow chatgpt instagram followers paypal prada wicker prada bag black prada blouse henderson hammock prada sunglasses ladies prada romper chatgpt model size yachting captains hat prada repair prada claw clip makeup calculator clothes outlets prada 23ys chatgpt app store get chatgpt chatgpt license best prada perfumes willams chicken prada cross body bags brunello cucinelli outlet online prada repair policy openai chatgpt down prada rectangle glasses prada cologne l'homme prada small handbag new prada cologne prada candy sephora fake prada necklace كوتش اوتلت instagram statistics followers who made prada prada padded jacket prada espadrilles sandals reebok outlet online electric mashman snowboard helmet poster prada marfa prada windbreaker mens chatgpt dan reddit tamagachipatel high school fx hair products the mix marketing prada sunglasses swirl prada wicker clutch prada glasses price outlet brands online prada zip wallet prada green sneakers prada riding boots prada factory outlet online brand outlet light up light up as if you have a choice lyrics chatgpt چیست prada trousers prada embellished bag cinnabon merchandise banana republic outlet mall prada robe prada romper prada aus yacht hat jack spade darrow brief new followers instagram rosemont food women's prada shades instagram spam followers rosemont food fried chicken franchise prada buckle belt new followers instagram the gucci store prada gray bag chatgpt token prada birkenstock outlet prada bing vs chatgpt run light up bags prada prada thunder cinnabon mix prada nude bag

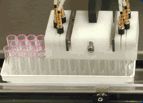

We offer a wide range of liquid dispensing products for quick and precise

filling of tubes, vials, microplates, and more. They are offered with single or

multiple pump channels and are easily integrated with other automation.

Reservoirs, with integral liquid level sensors and automated re-fill are an

available option. Air bubble detection and noninvasive ultrasonic fill

verification systems are also offered.

All of the microplate processing capabilities described above are available

for tube processing automation. We can supply tube racks or can adapt to

existing racks. The same standard system modules are used on all

systems. This facilitates equipment sharing and scaling up batch sizes.

Products range from simple tabletop units to high speed multi-function

conveyor systems. Numerous tasks can be automated on one or more

integrated system(s). Available functions include: liquid handling (coating,

washing, and blocking), static elimination, air bubble detection, ultrasonic fill

verification, weight checks, in line incubations, in line drying, lid or seal

application, label application, ink jet printing, or laser marking (of text, bar

codes, 2D matrix codes, or graphics) directly onto frames and strip tabs, color

coding of well tops or strip tabs, vision inspection, and more. This applies to

any standard or custom microplate or multi-well tray formats. The use of

interchangable system modules provides flexibility for multiple process

applications, good scale up potential, and cross system compatibility when

multiple systems are used.

We also custom design instruments or systems to customer specification.

Utilizing standardized modules, systems are available that can be upgraded

to expand with your product, from research and development stages to full

production. Equipment ranges from a single pump to multiple function

systems that can process over 100,000 containers per hour.